Designing the Mill!

- 2s982mit

- Mar 9, 2021

- 2 min read

Updated: Mar 10, 2021

This week, our team met up during lab to CAD the components of our mill, decide on the actuation methodology, and scope out parts to order.

We also looked at many off-the-shelf parts, including drylin carriages from igus, Rail Guideway Systems from VXB, and Guide Rails from McMasterCarr. We have decided on igus due to cost constraints and a teammate's familiarity with the company.

Drylin Carriage: https://www.igus.com/Product/925?artNr=TW-01-20

The dimensioning style of dimensioning the holes off of each other was chosen, as the priority of this part is that it is able to be attached to the sheet underneath it. Therefore, any error on the main datum hole (top left), should be reflected in all the remaining holes, so that the holes still align with the lower surface. We will verify accuracy by the ability to attach this part to the corresponding lower plate on our mill.

The linear guide platform is rather simple, though the length may be changed depending on our desired build volume and need to stop the carriage before reaching the end of the platform. The upper left corner was used as a datum, though the part is symmetrical, so theoretically any corner would be just as effective.

A few updates...

One of the main goals for this mill is to incorporate a threadless leadscrew into the design. A first draft of the CAD for the nut assembly has been made and all that I need is for the required bearing blocks to be ordered and delivered so that the linear motion module can be updated. The dimensions of the bearing support blocks will determine the shaft size and the dimension of the shaft from the base. From there, we can determine the appropriate spacing required such that the leadscrew and the linear rails are all at the same height. The current nut is designed with a pitch angle of 5 degrees, but this is easily modifiable. I believe the best course of action is to order the bearings and the bolts and to 3D print the first version of the nut. This will provide a sanity check as to whether the nut will work and I can check the pitch angle. We can also properly size the rest of the linear motion slide. From there we can spend the time on machining the nut out of aluminum. -RMHB

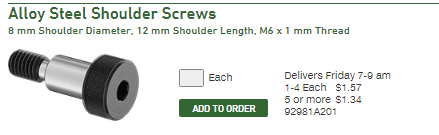

Parts to order:

Comments